Industrial retrofit projects – such as upgrading refineries, modernizing manufacturing plants, or overhauling power stations – often face major challenges with existing conditions. Facility documentation is frequently outdated or missing, and hidden issues or misalignments are common. Relying on traditional manual measurements in these complex environments can lead to inaccuracies, costly surprises, and schedule overruns. This is where 3D laser scanning combined with Building Information Modeling (BIM) comes into play. Scan-to-BIM technology uses laser scanners to quickly capture millions of data points and create a precise digital 3D model (point cloud) of the as-built facility. Originally developed for documenting industrial plants, laser scanning is now a proven practice for construction and BIM projects across industries.Below, we outline five key benefits of using laser scanning for industrial retrofit projects, with practical implications for decision-makers in oil & gas, manufacturing, power generation, and beyond.

1. Enhanced Accuracy and Detailed As-Built Documentation

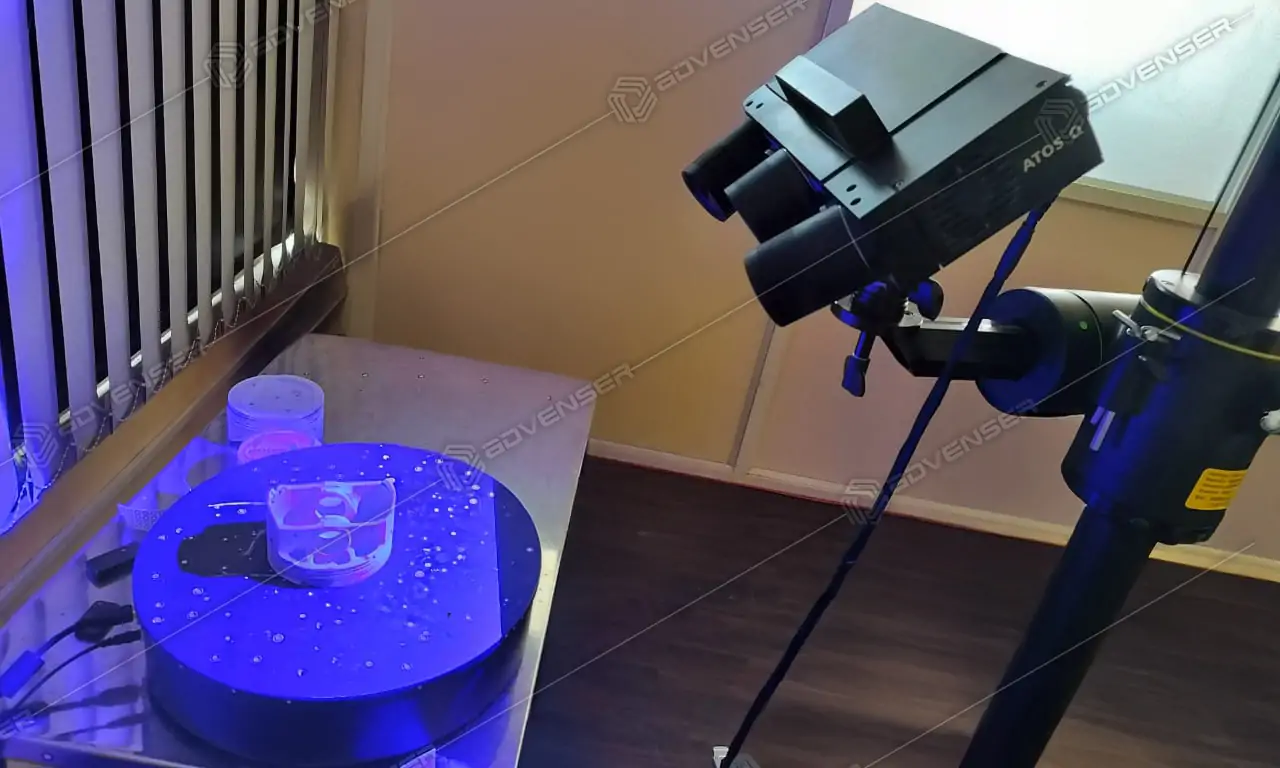

One of the most significant advantages of laser scanning is the unparalleled accuracy it provides in capturing existing conditions. High-definition laser scanners collect millions of measurable data points in seconds, mapping every pipe, beam, and wall to within a few millimeters of accuracy.2 The result is a high-fidelity digital twin of your facility – a 3D point cloud or BIM model that precisely reflects reality.

Accurate as-built documentation has practical, downstream benefits. Design and engineering teams can trust that the BIM model of the existing plant is correct, eliminating guesswork and assumptions. This ensures new retrofit components will fit right the first time. In short, laser scanning provides a rock-solid foundation of truth — every bolt, pipe run, and beam is captured digitally — upon which all subsequent planning and BIM modeling can build with confidence.

2. Time Savings and Cost Efficiency (Faster Surveys & Reduced Downtime)

Laser scanning dramatically accelerates data collection, which translates to significant time and cost savings in retrofit projects. Traditional surveying of a large industrial facility could take weeks of laborious measurements; by contrast, 3D laser scanners can document an entire building or plant in a matter of hours or days.3 In practice, scan crews often work during scheduled downtimes or off-shifts (even over a weekend) to avoid impacting production. This rapid, one-and-done data capture is invaluable in industries like oil & gas or manufacturing where every hour of shutdown can be very expensive. Reducing project duration and avoiding downtime directly improves the bottom line. A compelling case comes from a power generation project: a Southeast U.S. power plant converting from coal to gas was able to increase its output by over 30% and save more than $250,000 on the project by using laser scanning to expedite retrofit design and installation planning.

3. Laser Scanning Improves Safety for Personnel

Industrial environments – whether a refinery unit, a chemical processing plant, or a power boiler room – can be hazardous for personnel performing measurements and surveys. Laser scanning greatly improves safety by reducing the need for workers to physically access hard-to-reach or dangerous areas. The technology is non-contact, meaning the scanner can sit on a tripod or drone at a safe distance while capturing millions of points, instead of requiring engineers to climb scaffolding or squeeze into confined spaces.6 Fewer hours spent manually measuring in the field translates to lower exposure to risks like falls, heavy equipment, or hazardous materials. This not only protects workers but also keeps the facility safer by minimizing interference with ongoing operations.

Safety benefits are a major reason why many industrial firms are embracing laser scanning. Some oil and gas companies have even made it a standard requirement – contractors may not be allowed to bid on certain retrofit projects unless they plan to use laser scanning.For decision-makers, this means improved compliance with safety regulations and peace of mind that their teams (or contractors) can obtain the needed measurements without endangering staff.

4. Reduced Rework and Project Risks (Clash Detection & Fewer Surprises)

Retrofit projects are notorious for unexpected problems – pipes that don’t fit, clashes between new and old systems, or structural surprises inside walls. Laser scanning, when integrated with BIM, mitigates these risks by enabling thorough analysis and clash detection before construction begins. The rich and precise 3D model derived from scans allows engineers and BIM coordinators to run “virtual fit-up” tests: they can overlay new designs onto the as-built model to check clearances, interferences, and alignment. This process identifies conflicts early, so designs can be adjusted in the computer rather than costly fixes in the field. As a result, rework and change orders are drastically reduced. According to industry data, rework typically accounts for 12–15% of total construction costs, but using laser scanning to catch errors early can cut rework down to as low as 1–3%. That translates into hundreds of thousands of dollars saved on avoidable modifications, not to mention keeping the project on schedule.

By exposing inaccuracies or unknown conditions early, scanning gives project teams the insight to plan proactively rather than reactively. The result is a smoother retrofit process with far fewer “uh-oh” moments – something every project sponsor and construction manager can appreciate.

5. Seamless BIM Integration and Enhanced Collaboration

A core benefit of laser scanning is how well it integrates with BIM workflows, improving collaboration and decision-making across all stakeholders. Point cloud to 3D conversion from a laser scan, is done and directly imported into BIM software (like Autodesk Revit or Bentley systems) to create an accurate 3D model of the existing facility. This scan-to-BIM process means that architects, engineers, contractors, and facility managers are all working from the same up-to-date digital model. Communication becomes more efficient because everyone can literally see the same reality-captured model and trust its accuracy. For example, designers can annotate the model, contractors can plan tie-ins, and maintenance teams can review layouts – all in one shared BIM environment. Clash detection and coordination become much easier when the as-built model is part of the BIM, ensuring that new installations are coordinated with existing conditions.

Beyond the technical integration, laser scanning data greatly enhances remote collaboration and informed decision-making. The high-fidelity digital twin of the facility is a resource that can be securely shared with off-site teams, vendors, or specialists around the world. Stakeholders no longer need to be physically on location to contribute; a structural engineer at headquarters or an expert consultant overseas can perform a virtual walkthrough of the plant and even take measurements within the 3D point cloud.10 This leads to better-coordinated retrofits, as miscommunications are reduced and all parties can align on the plan using the same accurate visual information.

Conclusion: 3D Laser Scanning is a Powerful Tool for Retrofit Projects

3D laser scanning offers industrial decision-makers a powerful tool to de-risk and streamline retrofit projects. By delivering precise as-built data, saving time and reducing downtime, improving safety, minimizing rework, and enabling a truly collaborative BIM process, laser scanning helps ensure that upgrades or expansions are executed efficiently and right the first time. Forward-looking companies in oil & gas, manufacturing, power generation and beyond are already leveraging these benefits – in many cases making laser scanning a standard practice for any major retrofit.Embracing laser scanning in your BIM implementation not only mitigates the common pitfalls of working with existing structures, but also drives projects to be safer, faster, and more cost-effective. For industrial retrofit initiatives, the message is clear: an accurate digital foundation is key to successful modernization, and laser scanning provides that foundation. Investing in this technology and expertise will pay dividends in more predictable projects and better outcomes for all stakeholders.